.

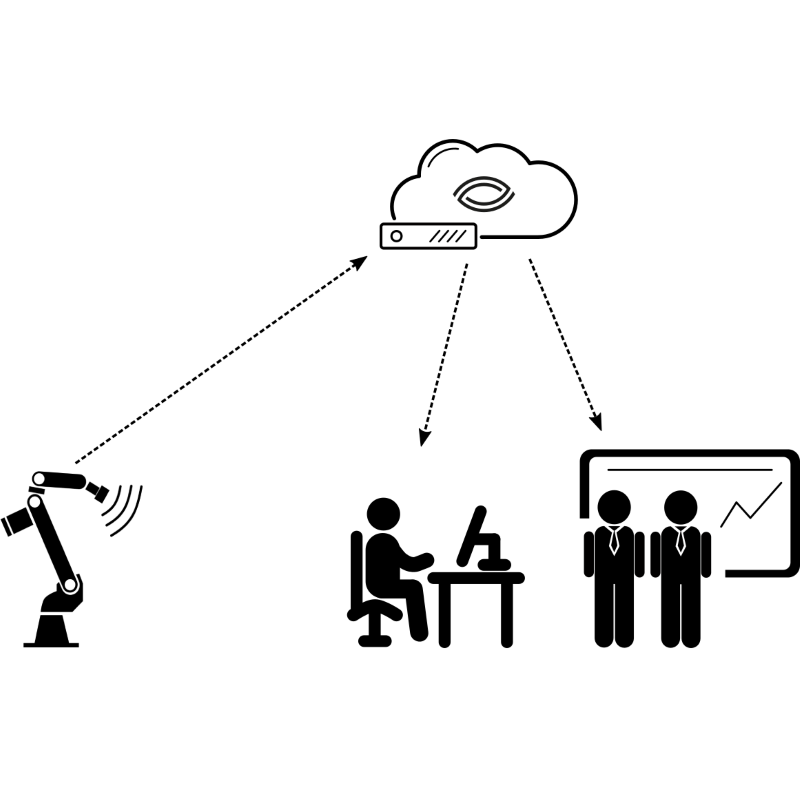

Robotic integration

The Winteria weld inspection system can be used with different kinds of scanners and robot brands.

.

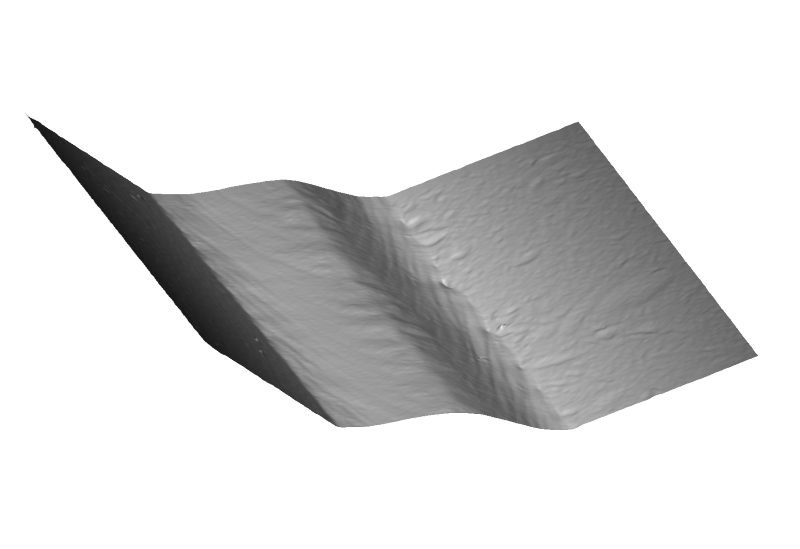

High Resolution

…

.

Access to data

This enables other personnel to access the data directly after the inspection and even meanwhile the operator or operators are performing the inspections.

The laser

Book a meeting with usThe choice of appropriate laser scanner is highly dependent on the application and the size of the features to be quality assured. The appropriate laser is selected depending on your specific needs.

A complete solution for quality assessment

View product pageWe supply a complete solution for quality assessment of manufacturing processes such as welding, cutting and bending. A laser profile scanner is used to acquire measurement data which is then analyzed and presented to the operator, production engineer or management.

Process quality can be presented either according to applicable ISO-standards or customer corporate standards

Depending of your specific needs, the system can be supplied in different hardware setups and with different modules.