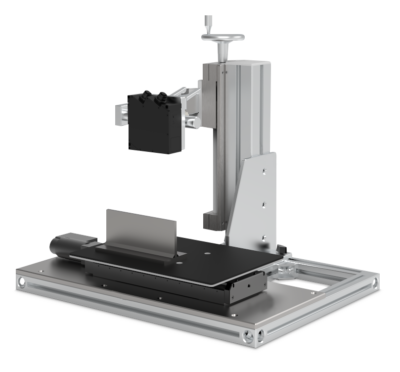

Winteria FLEX™

Winteria Production

Winteria R&D

Powerful Analysis Tools

Quality assessment of the welded joint. This includes bead geometry, defects and imperfections close to the weld. The common joint types are included with the possibility to add further joint types depending on customer need. Evaluation can be presented either according to applicable ISO-standard or customer corporate standard.

Quality assessment of the joint preparation of edges prior to welding. This includes angles, gaps, depth of preparation and more. Evaluation can be presented either according to applicable ISO-standard or customer corporate standard.

Quality assessment of bended plates. This includes plate deformation angles and bend radii along the bended edge. Evaluation can be presented either according to applicable ISO-standard or customer corporate standard.

Monitoring of welding process parameters. Implementation together with the qWELD module will enable a process specific knowledge database for identifying deviant behaviour of the process and the resulting weld geometry.